Total from 2020

1262 hr

2020 may have looked unproductive as a lot could had been completed,

though it was a very good year overall with only 216 hours applied to

the project which gave a very good start to other things that can be

worked on and hopefully completed this year.

- rear firewall / window trim and upper B-pillar plug was started last

year but will probably not start till early march when temperatures

start worming up so that plaster can dry up. may need to rethink seat

belt mounting as the original though will not work as expected.

- new headlights, plugs/parts for LED and HID housings

- Door, latches and other inner workings. Never got around to it in 2020

but that will be the focal point this year as its the last part of the

body.

- finalize HVAC bezel and inner baffle workings, May need

to locate some different heater and AC cores

- Fenders surrounding headlights and leading door sills and hinge

packets

- Any additional body or interior panel mounts

- Anything and everything else that needs to be done, rear upper spoiler

mechanism

Jan 9 1.5hr

Not a better time and need to move on. When out today to work on

the headlights. Figured out a different way to do the LED housing but

will need to do it next time. Will basically make a form around the

projectors to slip on easily and pour plaster in around it rather then

trying to carve it out.

Added surface for small projector on right side and bonded main

projector mounting for left HID housings.

March 10

46hr

Well its been 2 months and not much has happened. I guess

the gloomy sky and short days are not very motivating to get out and

do any work and thought would do some other work inside the house

but... again.. not much had happened. Well maybe should not go

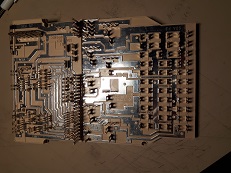

that far. Did some PCB layout for instrument cluster and came around

to 2 or 3 processors that still need to pull final decision on for

running it. More immortally laid out and manufactured few break-out

PCBs for processors and CAN drivers to test out and figure out codes

from the wheel combination stalk.

Having second thoughts about the interior fuse box and how its laid

out and its co-existence with one in engine bay. Not really a

problem with the engine bay going to the back of the car but more of

feeding headlights from it being in the back. Any hoo will have to

ponder and figure something out as it will require additional 6

fuses coming from somewhere. Problem is that the Acura/Honda

engine bay fuse box if really mother f....in ugly. maybe

something from other models as the controller will have to be redone

anyway.

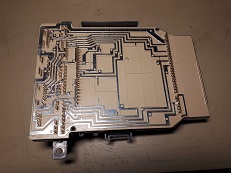

Last couple got the reverse internal wiring done of the MICU.

Figured to approach it in a bit different way. With all of the

connectors and pins, though to my self would it nice to be able to

hover a pin and show other pins that are linked together, so while

laying out PCB had IRECA moment as laying out traces. Use it to draw

the connectors and pins and label them with a net name so hovering a

cursor over a pin would light up other pins with same net name.

After 3 nights got the main MICU interior connections figured out.

This will now make the modifications to the controller board so much

easier rewiring some of the wire paths.

Figured to approach it in a bit different way. With all of the

connectors and pins, though to my self would it nice to be able to

hover a pin and show other pins that are linked together, so while

laying out PCB had IRECA moment as laying out traces. Use it to draw

the connectors and pins and label them with a net name so hovering a

cursor over a pin would light up other pins with same net name.

After 3 nights got the main MICU interior connections figured out.

This will now make the modifications to the controller board so much

easier rewiring some of the wire paths.

Over maybe the last 2 months was not completely wasted just one huge

update. Now just

need to focus on headlights housings and try to decode the stalk CAN

signals

April 7

A month had passed and no progress. However with Covid-19 stay at

home orders and lockdown decided to get some materials for plugs.

Picked up 2 bags of plaster and few cans of primer so hopefully that

will be sufficient to finish rear upper firewall panel and get the

headlight housing done. Its starting to warm up so need to move on

it.

April 9 0.5hr

carved and trimmed a bit of right light housing and filled in top of

the projector opening

April 10 2.5hr

Trimmed back exes from right housing, carved out left housing after

marking it to make it symmetrical and build up extra for projector

mounting.

Noticed that the openings are of different size compared to the

rings so their shape will need to be adjusted

April 13 1.5hr

Got the LED housings trimmed from some of the over flow and worked

more on the lect housing more to catch up to the right side. Did a

quick measurement between the new HID and LED housing. What it looks

like they will be very similar in height so to prove it and since

larger projector hole was already cut, got the projector wrapped to

make cone and filled in around it thus further building up the

housing. Will trim it and see how it will compare it to LED.

Will also need to do the smaller projector hole made and build it up

just like the larger one. Also build up some of the lower

areas on the LED housings as they still need lots of build up

April 18 1.5hr

Focusing on the HID headlight housing plug as that will guide the

shape of the LED projector housing, provided that they will not be

too tall.

Shaped right housing around main projector, however looking at it

came a thought that it might be pointing too high up rather them the

ground (road) so will need to test that theory by mounting the

projector and powering it up to see how the bean hits the ground.

Never the les its roughly shaped also cut down on the height of it.

Got the second hole cut out for for smaller projector however after

cutting out left and comparing to the right decided not to start on

the trim ring. So after some remeasuring and reconsideration decided

to make just the main ring on the left main projector. Will need to

wait for that to cure trim it and try the light beam projection test

before moving forward

April 22 10hr

Got around at looking at the prototype of LED board for break

splitter where it burned up some of the LEDs for some odd reason. It

turned out that the center thermal pad is connected differently

between orange and white LED's, so removed the link going to cathode

and they are free floating now. After removing offending links on

one of the proto boards, build it up and it works perfectly with

less then 100mA consumed by white LEDs. Updated PCB layout in case

needed to have some extra made and production will get those as

well.

Finished controller board which is part 2 of the setup. Back of LED

board will solder up to it and make it a single unit that can be

mounted in the splitter it self. This is white / amber setup and the

controller can be configured to to be white marker with blinking

amber and optional shutdown of white while amber is on. OR white

marker with sequencing amber and optional shutdown of white to

enhance the amber turn signal.

Sent out controller board for printing and will assemble couple once

they arrive.

April 24 2hr

got the left headlight trimmed and after looking at left and right

decided to alter left to how the right looks like. So got some tools

and started carving extra material and removed any thing that

interfered to make it symmetrical to right side.

Trimmed some more of the right housing to see how it would fit into

the fender. If it was not for the fact that the main projector is

huge and is moved forward quite a bit. Top id it sticks up more then

wanted.

Got a cone made for the smaller projector and got the 2 projectors

fitted back into the bases. Also fixed in the flat mount on left

housing as it fell off

April 25

quickly pulled off the projectors from housings. Knew that the

material was starting to thicken up while doing the smaller one. So

back it if had some voids. so before pulling the cone out mixed some

small filler and filled in the void very quickly.

May 2 1hr

Continued on with headlight housing trimming. Both are hard to make

fitting of, HID is high on main projector and will have to extend

backwards so that lens can have reasonable flat curvature. LED are

wide and protruding out words. Have this feeling this is going

to be a PITA to get something universal. Had to cut it short cause

needed to get out to town.

May 3 2hr

having to make short day yesterday and probably good that it did.

Had to think about it for a bit. lens will never be exactly smooth

to the fender/bumper and will have to have some sort of protrusions

but they will be minor. Never the less starting to get common flow

between both housings and it might be OK with the space that

there is to work with. Need to re-adjust how the housings sit and

move them bit inwards to the center so that will gain bit of space

on the outer side which will allow for smoother edge. if that is

fixed then everything should be nice and smooth to fender. Duing so

will need to adjust some of the bumper and fender cut line which

should actually have nicer flow.

Re-shaped slightly right housings and made templates to transfer to

left side. Trimmed left housings based on templates. Unfortunetaly

trimming left LED housing had it cracked as there was not enough

upper material to hold it together, not a major crack but just

enought to get you going. Also trimmed HID housing and made hole for

auxilary projector, set it into place building up the ring and

filled in couple other small surfaces on right projectors.

Used wood glue to bond the left LED projector but will need to get

that trimmed and filled to pair up with right one.

Slowly but surely, once the wet days are over hopefully will have

something to mold and made parts of soon. Then on to the rest of the

pieces,

Should start doing something on the rear firewall trim and lower

panels

May 4 1hr

trimmed the small projector ring on left housing. Those projector

covers will need to have some shaping done to them as they are quite

thick. Will need to move those housings inward and try to adjust

horizontal position and see how parallel they are to each other

before proceeding any further in having them shaped.

May 8 2.5hr

spent long time adjusting fender and both headlight versions to fit

in. Think got it to a point where they will be interchangeable

utilizing same fender cut outs and chassis mounting points.

May 9 2.5hr

Changed focus today and decided to look at quarter panel alignment /

mounting as reason to have rear firewall panel moving forward of

having plug made. In order to do that had to remove any mounted

panel bolted to the chassis. So having the quarter panels just

sitting on the chassis with one bolt loosely holding by very rear,

it seams that they align with the rockers problem is that they are

pushed out too far outward and the 2 right mount weld troughs are

placed in incorrect location by about quarter of an inch. AHHHH. So

came the dilemma re-drill the panels and fix the holes plus any

offsets or remove the weld through chassis nuts and put them in the

correct location. Alter looking and contemplating decoded to do the

right thing and remove what's there and put new ones in correct

location. Figured if doing it may as do it properly. Left side will

just have to have it drilled and welded in proper location. Problem

2 now is that the upper rails will need to be relocated as well by

moving them inwards so that hinges would mount up as it looks like

they need to move around half of an inch. Other thing is that roof

may need to be possibly narrowed though as it needs to be redone

that may not be a big of a deal. Same may apply to the engine lid

though that will be just a matter of trimming sides.

Positive side of this all is that quarters will mount right against

chassis as they where meant to be, no filler panels just fiber

filler from panel to chassis tube as it was meant and everything

will be water sealed.

Other good news is that the break trim light controller board

prototypes came in. need to components to arrive in order to get one

assembled

May 10 1.5hr

Assembled all of the passive components onto the controller board

that had on hand. Waiting for some P-mosfet drivers and come

rectifier diodes. Good thing that there is only 2 to be assembled

cause those 0805 resistors are small, in hind side should have gone

with 1206 as they are bit bigger. May try to redo the layout to see

how it will fit. Also assembled second LED car after cutting traces

from cathodes to the center pad

May 15 1.5 hr

Continuing on with the quarter panels. After removing the threaded

weldin captive nuts last week, they had to be re-drilled or

elongated / slightly moved over to have new sets welded in on the

right side. New nuts where welded in and ground to finish of the

surfaces then primed to protect metal from corrosion.

May 16 3.5hr

Continued on with left quarter. Drilled holed in panel and frame

after having it aligned with right, welded in threaded weld in nuts.

This makes the quarters aligned and mounted with one exception, the

upper tube that's is used to hold deck hinges and is support for the

quarter panels needs to be moved inwards by half inch. Had one of

the tubes moved outwards last year cause noticed that they where not

placed evenly :(( so this will be re-do of re-do. Having quarters in

this location they align better on the split to the rocker panels,

secondly they mate smooth around striker location / door seal

which is a major thing when making cabin water tight.

Couple side effects of pushing quarters inwards. Engine lid is too

wide now by close to 3/8 of an inch on each side depending on gap.

Secondly hinge mounts will need to be adjusted to accommodate for

the change quarter panel mounting. And lastly, roof panel, have not

measured it yet but it may need to be narrowed as well.

Either way good progress or creation of more work or re-do

May 24 2.5 hr

long weekend but had other things to do and just got on to the

project. Had intension of doing headlights but never got to it and

just did the back firewall interior panel. Never the less put some

filler material so that filler would not go into cavities. Had to

pull all of the outer edges around the panel as they are

considerably off comparing to the lower B part, carved out some

extra backing foam so that the filler hopefully would have some

extra bonding area. Built up all of the outer areas out of filler.

the thing is that it will be heavy and tight so taking the panel out

will be tricky. However as the quarters now have a resting

place tolerances will be tight and close to the final dimensions and

will finaly be able to finish that panel.

May 25 1.5hr

removed all of the quarter panel screws, moved it outwards and up a

bit. The panel is heavy and tights as predicted. While taking

out it split in half :( ahhh so will need to bond it back together.

The other thing is that cause its so tight the outer fillings are

showing some cracks so fill need to figure out a way to keep them

bonded together before they completely brake off. AHHHH

Should have completely removed the quarter panels, guess that's what

happens when you rush things.

So once day job finished, took another look at the panel. Left side

broken off into smaller piece and survived however the Right side is

2 3rds and is the one that actually cracked the add on material.

Trimmed both sides to give way of better fit while test fitting but

unfortunately right side just did not had the grip to hold it all

together and trying to hold it in place proved to be futile.

Anyway carved away extra material on both parts and removed foam

backing on the main part. On left side embedded mesh and bonded the

new material with flat part on half of the edge. Once cures will

carve out remaining portion and reinforce remaining edge. Right

side, since it was not possible to hold the material in place

properly. Had to discard it and just embedded part of mesh strip on

back side and remaining part will be embedded into new part once

laid up again. However contemplating to bond the 2 parts together

first to make it hole. So unfortunately this will delay in

making any progress on the plug

May 27, 2.0hr

Had couple of days to ponder how to bond the back firewall plug

quickly but making sure its still solid and decided on 2 step

process. As the panel is based on 2" foam board the first step is

from back side as it provides best place to straighten it and then

from the front. So carved out 2 channels on the back first all the

way across just under window ledge down to the surface coat and a

second channel on bottom to further reinforce the edge which will

also re-bond some of the chipping filler roughly 10" long. Might

extend the lower channel further and perhaps all the way to the

edges but for now that will suffice. Now to keep everything straight

and together a solid steel rod would probably be best though as all

stores are closed due to Covid-19 came out with the idea of using

nylon mesh as best option. It would get embedded with in filler and

the filler would bond to the filler used on surface which will give

a solid thick bar. Thinking about it should have glued on some of

that nylon mesh on back side and embed some on the front when first

making the panel. As a matter of fact should have done that on all

large panels that tended to sink down especially on the rear deck

lid. Second part will be to do similar thing on front side, but as

its really flat and like to preserve its shape may need to do the

reinforcement in 2 steps and while positioned in the car while

remaking the right side. Will sand down a channel on the surface

across from side to side for stability of entire panel then make a

channel on the crack and again embed some of that nylon mesh in the

filler which will prevent bending the other way. Once all of that is

done the panel will be removed and let it sit aside to cure before

doing any shaping on it

May 28, 2.5hr

Continued on the rear firewall panel, put some additional filler to

prevent filler from sticking to chassis and fitted panel in place.

Sanded down valley on face and filled it in with embedded mesh

suspended in the filler. Build right side embedding the mesh tamps

that where fastened previous day. Will need to have it dried before

taking it out. at least remove quarters so that the panel will lift

out easier. Will most likely have to wait a week so that the

moisture will evaporate as its very wet from yesterday.

May 29, 0.5hr

pulled quarter panels off and pulled the panel out, Shaved some of

the over stuffed filler and put it aside to dry.

May 30, 1.5hr

Took out the rear panel out into sun in hopes to cure. went out

later in the day to work on headlights, however while opening the

doors forgot that the panel was propped against one of them. So

instead of working on headlights ended up fixing cracks on the

panel. AHHHH. Well at least the right side surface is getting

re-bonded.

June 2, 2hr

Got the rear firewall plug in after some trimming and shaped right

inner contour. Filled in some gaps on right side and a hole that was

made after trimming as it seems it was made too thin. Re-skimmed the

large hole after embedding mesh in.

Adjusted and centered HID headlights. Had to move right side inward

1/4 inch. build up upper inner rim so that seal can sit on it. It is

right against fender now but will have to trim it down so that

gasket can be fitted in.

June 6, 2hr

Further shaped HID headlights, keeping on forgetting that the fender

is not changing and trying to keep same profile of it. Though it

will rise by about half inch and need to keep that in mind. Got the

cut out shape to ideal shape and position. Shaped the housing

further also got the LED to similar shape that it will fit same

opening so they will be interchangeable. Further filled in back

firewall and it looks like its flat yet again so will need to work

on it trying to get it to shape. Will have to get remaining mounting

tabs done and welded / bolted to all of interior panels. Will have

to think about mounting of roof panel too.

June 7, 1hr

When out for a quick look to check on the headlights. knew that the

extension behind mounting face was way off so decided to build some

of it up and correct angle of it. Embedded some nylon mesh into it

so hopefully it will hold it together better and even if its off

will be able to add it later so that it will span across the width.

Doing one side only at the moment of both HID and LED housings as

there is no point doing both sides incase would need to do major

redo on the design. One thing though is that some of the areas on

either housing are rather thin hoping that will not run into an

issue where it will be impossible to cast. Time will tell and

hopefully will try to make them bit thicker

June 8, 1.5hr

Spent good time shaping and carving the 2 right HID and LED light

housings, got them to a point where they are very similar in fender

opening shape. Still rather malleable and prone to easy breaking so

will wait another day and hopefully they will be in good shape to

further shape them. Very happy on how they are coming out even

though the fender needs to be slightly altered to provide some of

that needed space for the height of HID projectors. There will be a

very thin inner upper corner and will try to somehow make it thicker

for easier casting but will have to see how the final work will come

to. Additional spot will be with LED inner vertical side.

Will focus on the outer shape of the housings for time being and be

closer to getting the fender reworked and completed.

A lot more work needs to be done around back firewall panel in order

to get it to mold stage which would leave just the lower back

covers before floors can be welded in

June 12 3hr

Contoured and sanded flat back firewall plug. Trimmed left HID

headlight. Skimmed back firewall plug and build up extension on left

HID headlight housing.

June 13 2hr

found that the thickness around the very top glass and roof of the

back firewall trim is not same from left and right, got that shaved

to same thicknesses. I assume that was caused by the crack of the

back panel. Trimmed further right LED head light so that the

projectors will slip in easier. Debating of making metal mounting

bracket rather then having them mounted directly to the housing.

Need to do the left one and build it up. had to build up left HID

housing further but unfortunetaly cracked the extension so will see

how it will hold up when it dries.

June 19 3.5hr

shaped back outer edges of rear firewall trim. Shaped further

headlights, build up left LED housing

June 28 1hr

Did some trimming of left LED headlight.

July 4 3hr

Trimmed left HID headlight, HOWEVER. looking at the piece of left

fender it was decided that it is warped and it will be hard to use

it as means of proper measure. SO took a big jump and cut out

headlight openings in the fenders.

July 7 2.5hr

Had some time to think about the lights and came out again to have a

look at them. It ended up to be a simple problem of clearance, glad

had the time to take a break and not have done something stupid.

So trimmed of some of the housing which resolved clearance issue

making the fender sat down properly. Looking at it further it maybe

best to have the fender pushed out to the sides as well not just the

top. Build up top and outer sides of the left housing as they where

sunken in slightly. Had to also build up back right bumper cut out

to match left side while building up left housing.

Removed back firewall plug, however right lower corner broke off,

had to bond it reinforcing it with fiber mesh. With the plug out

used the paper as separator and build out rough right speaker box.

Will need to get final top surface before removing it.

July 9 0.5hr

Squeezed bit of time in while doing brake job on wifes daily

driver. Top coated surface of the right speaker box and

build-up/extended top and bottom of the box so that it would reach

fully to the bottom of the floor and bottom of upper panel.

July 14 0.5hr

Parted left side speaker box and laid up first layer of mold

plaster.

July 15 1.5hr

Build up left speaker box to point where top layer will need to be

shaped with thicker bottom edge around the floor. However decided to

leave it to next day to finish top coating and have the main

structure set up to avoid possible damage to it.

Shaped some of the surface of the right box, but will need to figure

out a way to mount it in place some how now that its pulled of to

finalize all of the dimensions. Need to wait for left box to be

pulled off to get some mounting figured out. Also will need to put

the upper panel back in to figure out bottom edge and return to the

storage compartment for a clean finish.

One thing that is high on priority are the fenders and headlight

situation regarding their general shape/fit and mounting. Need to

get that knocked out soon so other items on the list can be worked

on.

July 16 1hr

Surface leveled most of left speaker box with exception of clamps

holding back on the center tunnel cover. Will remove it next day to

let it cure but hopefully it will not peal off and will be able to

fill in the holes first occupied by the C clamps. Trimmed area

around right headlight.

July 17 5hr

got out late however managed to put some solid hours in though the

work does not show the effort. Pulled left speaker box, however how

it was build bottom part around C clam cracked while removing it.

However as this needed to be reinforced after take out that was

easily fixed by backfilling from center of cavity.

Now that the tunnel was free it was removed attention was put

towards ways of mounting it to back firewall and how the speaker

boxes where going to be mounted as well. Figured a best way would be

to use either screws of bolts from inside of storage cavities with

additional screws holding it agains sides of tunnel trim. After

making some templates to reinforce sheet metal and having it welded

in. A lot of time was spent to clean off rear panels of tunnel as it

seems they never where primed. Day ended after primer was applied to

all cleaned up metal as to prevent it from any dust settling on the

paint.

July 18 7.5hr

managed to put some good hours into the car today. not the proper

mounting bolts but never the less used some screws and bolted center

tunnel into the rear firewall. With it mounted its now possible to

work on the speaker boxes and upper rear firewall trim. A huge

amount of time was spent on getting bottom of the upper rear trim

straight. had to remove some of the foam structure to clear

frame tube which was covered by filler to make hard surface. Got the

speaker boxed shaved to level, seem like when did them other day

they where protruding too far forward so had to shave them. Also

trimmed inner wall and top to mate with the upper panel. Used couple

layers of 1/8 cardboard as spacers when back filling speaker boxes.

That space will be filled with upholstery later on when finishing

off. Also re-skimmed surface of the speaker boxes.

Will have to get cutout of 6x9 speaker and fit it onto the face to

make indentation so that the speaker will sit flush. Last thing will

be a flat panel all the way across to cover the cavity and speaker

box to make it look as if there is no storage cavity.

Will need to wait few days for all the pieces to dry off before

doing any sanding or any other work on them. Will need also add

return that will hold carper in the storage cavity but that will be

the last thing before making molds

July 19 1.5 hr

Quick look at the speaker plugs, trimmed, cleaned up and sanded flat

build up some corners to make them symmetrical and sharp. Tried

lining up 6x9 speakers, they fit but will need another half

inch to make some returns and provide some area for grill to fit on

top and not having anything exposed on side edge.

July 24 1hr

Quick adjustment of speaker boxes trying to get them squared and

symmetrical between left and right

resurfaced and filled in some areas

July 27 2.5hr

had an itch so decided to head out to garage. sanded down some rough

spots on the speaker boxes and flattened speaker face. Still mulling

about it but may try to sunk in the speaker mount face about 3/8 or

half inch and move it inwards so that would not have to enlarge the

box any further unless will put 5x7 rather 6x9 speakers. Scribed

upper panel of how much bottom lip will need to be sanded down so

that the bottom filler panel will sit flash with it.. Probably will

have to redo it but decided to trim out rear window to contour of

the rear deck lid. So one last thing to work out are the upper

seatbelt mount points and how they will be fed through the panel.

One that is completed will prep the plug and pull mold from it.

Resurfaced speaker boxes fixing some of the corners and filled in

around the window and try to get it smooth

July 29 3hr

cleaned up lower lip on rear firewall panel making it symmetrical

left to right. Build up more of a slope so it would not look too

sharp. Will have to carve out indentation on outer edges to mount

seat belt loop.

Sanded down speaker boxes and extended bottom so it would not

require any flaps when making molds. they still have some work to be

done before being ready. Have to carve out recess to mount speakers

in making them flush with finish panel.

Changed direction some and decided to look into HVAC blower box as

it was sitting since last year and figured should finish it so it

would be ready for mold making. Thought of making a lip around the

motor mount to seal better as OEM but after thinking some thought

just using an O-ring like gasket to seal it and it would be much

easier to make the opening and making the mold and part. carved out

clearances so it would clear chassis trimmed part around radio for

wires to pass through and into fuse box. Sloped some edges for

easier removal from mold. filled in holes after foam removal

July 30 2.5hr

Started with HVAC blower box, sanded down the filler and primed it.

Few dings here and thereto be filled and it will me ready for molds.

Decided to go with 6x9 speakers after looking around and realizing

that they need to sit 3/4' below surface and with the grill right at

the edge means some small part will intrude into the resting block

on the center tunnel. Good part is that the cut out will not be

necessary if the grill would be omitted as the speaker it self would

slide under the resting block.

Got some carving tools out and carved out 3/4 inch + deep cavity.

Did a first rough fill injust to get some solid surface to work with

Aug 1 1hr

Unbelievable... its already August. Doors are not mounted yet, glass

is not fitted and have not done any body work yet. Really need to

get my rear in gear and get the door fitted and get any mechanical

stuff done and move on to the body. Though there are lingering

headlights and the fenders to contend with so they need to be done

too at least figure out how much in any those fenders need to be

altered.

Any way, got out for a short time to clean up those recesses on

speaker boxes and filled them in so they are getting closer to be

ready for molds which will ultimately leave just the cover panel

which should be really quick job. Now thinking about it should the

resting piece up on top be part of the panel or something be molded

into the upper panel. Something to mull it over and if it

would be part of the panel then speaker boxes would need indentation

hummm...

Aug 4 1hr

Spent some time again on sanding down speaker boxes and HVAC blower

box. Filled in some indentations.

Aug 5 0.5hr

A quick sanding just to get rid of poky corners and a heavy coat of

primer on speaker boxes and HVAC blower box. Though thinking of

cutting down on some of the corners on the blower box to give ways

for extra space for like electrical splice connectors etc...

Thought of a way of getting seatbelt upper mount mounted will have

to see how it will work next time out

Aug 7 6hr

did not felt like doing any thing and it supposed to be a quick

outing to garage but ended up spending a lot more time then planned,

maybe its the fact that did not see too much progress with the car.

Marked down edges of lower B and speaker boxes mating spots on

bottom of rear firewall panel while having chance doing it and will

most likely proceed with finalizing the panel for mold making as it

is large and dont want to have it cracked. Also working on adding

extra frame to complete seat belt mounting tubes will most likely

inter fear with the plug construction. Will have to figure out final

upper loop area after figuring out how the loop will be mounted.

Most likely the part will have to be altered.

After sanding down the primer on the speaker boxes and blower HVAC

box plugs, skim coated them to get it to mirror finish before

making molds. Still have to look into carving out any extra parts

out of the blower box and ducting options for fresh and recycled air

baffle and how it will work in general.

With the easy part done focus turned into the frame and seat belt.

Added extra tubes after having them cut bend and welded back

together before welding it onto the chassis. this part of the

process turned out much longer then anticipated but glad its done.

Still have to add some extra material to finish it off but will have

to look into roof mounting as the area will be used for the mounting

of sorts. Will have to dig up the seat belts out next time to see

how the loop will mount and routing of the belt will go but it looks

like it will be bit lower then shoulder height and there may not be

any adjustment for it.

Aug 8 1.5hr

took longer then expected for what it was, never the less sanded

down speaker boxes and HVAC blower box with 220 grid and applied 2

heavy primer coats. Still will have to fix back side return but the

plugs will be ready after the sanding for mold making

Aug 9 3hr

spend another few hours on reverse engineering interior fuse box.

getting closer to getting it figuring it out though most likely will

not use everything that was in it and will have to remap few

circuits

Aug 10 2hr

Went back to decoding further interior harness while the plugs are

drying

Aug 11 4hr

More time on the interior wire harness,

Aug 12 3.5hr

More work on the harness. Thinking since having an extra key wire

set. thinking of wiring it up to what its going to be and cleaning

up some wires out of the loom. Maybe will head out and get another

one as extra to work on and have extra wires in case some will need

to be extended.

Aug 13 0.5hr

Its has been couple of days since the plugs had been sprayed so the

primer had should be fully cured. Sanded down the HVAC blower and

the 2 speaker boxes. Working on the wiring last few days made me

thing of finding more space for the wiring as there will need to be

at least one splice block so perhaps the blower box will have to be

trimmed to as much as possible. Also looking at the speaker boxes

the way they are made and upholstery in the storage boxes. Thinking

of bumping out one side so that the carpeting would go under it

making a nice clean finish. So as this would need additional 1/4 3/8

inch may as well go all the way up to the front and make a clean

edge around the cut out for the speakers.

Aug 14 1.5 hr

Was not planning but as was out doing yard work figured to stop by

and have a looksee, well it turned out to be fairly productive short

stop. Filled in some corner chips and inner corner on speaker boxes.

Should have squared off outer corner as it will be bit harder after

extension is added now that adding 1/4 inch will not be big of a

deal. Will also add small just as much to the upper panel on bottom

around the storage box. Filled in bottom of upper rear panel to get

any larger voids and chips out. also filled/build up area around the

center console on the rear panel to add to the strengthens of it.

Made 1/4 inch panel of filler which will be sliced and used as

the thickness addition to the speaker boxes

Aug 15 1hr

Quick trip to garage, extended or moved out the outer edge of

speaker boxes after slicing the 1/4 inch flat piece for both sides.

Still debating on the HVAC fan box if I should have the corner

trimmed to get some extra space. Also added extra piece of the 1/4

inch flat piece to extend around the storage area to hold upholstery

up.

Aug 17 1hr

Short time out again, sanded down any large bumps on the speaker

boxes and resurfaced hopefully will not take too much time to make

them flat again. Built up storage compartment edge and rest area for

cover to sit against it.

Aug 22 3.5hr

Not sure if looking for parts counts never the less its part of the

total. looked for set belt retractors and rear window regulator to

make up the wet wall and see how the mount point for the upper loop

will work. Had some creative insight to the HID head lights and how

close the inner larger projector is to the edge. Thought of having

it moved out slightly which would push everything out to the sides

and the smaller projector still would be flush to the lens. Have to

have another look but it looks like thats the solution to the

very non existing edge around the larger projector

Sanded upper rear panel mold and the 2 speaker boxed and had them

primed.

Aug 24 4.5hr

Few small trips to garage today working on the plugs. Sanded and

build up speaker boxes and got them to condition where they where

primed and ready for final sanding. Will need to have the primer

cure for a day or 2 and have some of the sharp edges softened so

they would be ready for molds. Got the edging around center console

worked out along with apholsterly retaining edge. Got it filled and

sanded to fairly smooth surface though it will still need some work

done to it to get it glass smooth. Also need to look into upper belt

loop as that will be the one are that will hold of making a mold.

Not sure about the roof mount. may need to bup it out or just will

take the chance to have it be way it is. other area is around the

glass, not sure if it needs extra build up though it will require

some cavity filling.

Lastly, HVAC blower box. Decided to trim it down around wire routing

after verifying its fit.

Extended or rather added extra material on the inner edge of HID

housings effectively moving them outwards by 3/4 of inch. this will

allow of extra gap from edge of housing lens to projector to allow

for smoother transition. May add some thinckness on back of smaller

outer projector to move it backwards to clear the lens, will have to

see how it goes after some controuring

Aug 25 2hr

Couple more hours working on the plugs. Sanded down speaker boxes

down to smooth finish, they should be ready for pulling molds from,

however found that one of them has couple small depressions on the

face of the mounting face of the speakers and one of them looks like

its right on the mounting point so dont want to take a chance so it

will need to be fixed. Though forgot to do that and will need to

wait till next time. Sanded down HVAC and put heavy coat of

primer on it, hopefully it will be ready to sand down next day as

its rather hot last few days. Carved out recess on the storage box

panel rest area and build up around window opening and filled in

sides as help to help of mounting flanging. Trimmed HID headlight

housings by adding 3/4 inch on inside. The extra space makes a world

of difference thou it does not look like much. Have to add extra

filler in the left as it was carved out too much on angle.

Aug 26 0

a very short time out to garage after family day outing. Did a quick fill of the

speaker voids and build up rest of the upper panel's parting support

and skimmed HVAC fan box

Aug 30 0.5hr

sanded down HVAC and had it primed ones. Same with speaker

box, quick fill

Sep 1 0.5hr

sanded down HVAC and skimmed, Sanded down rear upper trim panel and

gave a light coat of primer

Sep 4 3.5 hr

Saturday so another yard work day making day short for play. Had to

do some maintenance work on daily driver but still squeezed some

time to work on the plugs.

Got the speaker box mount surface fixed and finished, knocked down

all sharp corners for easier mold and part making. Not sure it is

going to be wrapped or be just plain part as it will sit behind

cover panel though it would look better (finished) when its covered.

So speaker boxes plugs are done.

Sanded down back firewall panel and put heavy primer on the parting

and around window. one thing its still waiting on are the seat belts

loop mounts not sure how they will fit and work so will need to

wait. last thing to do will be to get the window area opening

rounded off and the panel plug is virtually ready as well. Trimmed

off left HID housing finally, it fits so much better now. will have

to get them to shape at least outer part and get the fenders done

and remade as that will be a huge move forward.

Exended upper lid of LED left housing as it was short and low so

that can be worked on as well

Sep 19 0.5hr

Added returns onto rear firewall panel

Sep 26 1hr

Been busy with other things around the house so did not much time to

work on the car, yah \ok lame excuse. Anyway was working on daily

driver today again to prep it for winter and in between squeezed

some time. So added bit of a build up with some old short strand

around the headlights trying to get it to lift up and add some extra

clearance for the housings. Will have to knock it down but its at

point that it has fair amount where some of the underside of the

fender can be ground down . Will have to fill in any of the rough

surface and smooth it out.

Sep 30 4hr

Believe cluster power board maybe fully routed. It has all regulator

circuits for cluster and GPS/Communication modules and power

monitoring and switching logic to regulators on board. Will have to

run simulations on them all before producing the boards and any

assembly.

Oct 2 0.5hr

did not had too much of free time but working on daily driver ground

and sanded overflow and high spots on the fenders around headlights.

Really need to get them shaped and adjust other small areas and have

new molds made and remake the fenders

Oct8 (2hr)

Forgot the pain in the rear of driving across town. Went out to get

a pail of resin to start laying up molds for the plugs. Need to have

them finished before cold sets in

Oct 9 3hr

With all of the plugs lying around and getting late in the summer,

not wanting to crack any of them picked up pail of resin on friday

to make up all of the molds, even if they are just going to be

sitting on the plugs. Unfortunately they will have to be made in

break away pieces most likely into 3 different parts due to odd

contours. Will leave the upper rear panel alone for the time being

though probably would not be a bad idea to have it made. However

with 2 HVAC boxes and 2 speaker boxes and 5 other non related pieces

it will be busy day so decided to leave that panel alone for time

being as it will be crowded in garage. Will try pulling it once

other pieces are done and out of the way. Got everything parted

waxed. Once PVA dries over night will fiber glass them in the morning

Oct 10 4hr

So got out to get all of the parts glassed. As always had to cut a

lot of fabric as had to make 9 parts and in reality it took 7 hours

from start to finish but approximated to 4. So now have speaker

boxes that will need additional half part to be made with additional

support after the fact that will be bonded on the inside. The 2 HVAC

boxes will need 2 additional external parts for the mold cause of

their shape. Will have to pull parting from them and move on to next

step next day out

Oct 11 2.hr

Did a first trim to get rid of the rough edge fibers. Will have to

wax and PVA after setting up parting on the speaker and HVAC

molds.

Oct 16 1.5hr

Been few days, figured the glass is cured so got out parted HVAC

boxes waxed and PVA for tomorrow including speaker boxes.

Speaker boxes will need 3rd piece as well but they will be made as

separate pull after adjusting the plugs.

Oct 17 2 hr

continued on with the molds. Had to cut some extra mat and laid up

second parts for the 2 HVAC boxes and right speaker box.

Unfortunately run out of resin for the left box and probably its not

thick enough in one corner for the right one. Need to get another

pail to lay up the last parts for HVAC and left speaker box.

Will try to make parts this hear so that they can be fitted in and

mounting made during cooler temperatures

Oct 22 (2hr)

Another trip across town for pail of resin. while there picked up

quart of bonding putty, seen it last time so will try to see how it

works bonding brake splitters and forming PCB guides. Well at least

that's the hopes of it. If it works OK will try it on bonding door

skins to the inner panels and hood. Could be lower cost alternative

to 3M epoxy

Oct 23 4hr

Should had been shorter visit however as the molds where not

stripped of previous parting so had to remove those first. Not sure

but the longer curing time may had allowed separation of the parting

material to be much easier then just with just 24hr wait. Will wait

longer with next molds/parts.

Never the less parted last pieces for HVAC boxes leaving tops open

as that will be only way of laing up the parts and tops will have

opening so then can be made at later time. Also was going to make

mold of the upper rear firewall in one part though possibly leaning

to wards 2. Last minute decided to make it into 3 parts so that took

some time to make as it is large part.

Waxed and PVA all of the plugs for next day to lay up some glass on.

Oct 24 5hr

laid up last parts of HVAC boxes and second part of left speaker

box. Also a main part of rear upper firewall panel is done as well.

Two more small parts are next and will be able to pull parts from

it.

Speaker boxes plugs will need to be trimmed and fixed around one of

the edges to make up a mounting/ resting corner that will need to be

bonded in as after the fact.

Drilled and trimmed right speaker box and had it split. Will

fix the plug for 3rd part together with the left box.

Laid heavy layer of filler on fenders to blend in the raised

headlight opening. Will have it sanded and further filled in to

contour.

Will have to do something with fenders and bumper to get it flow

properly as it has bit of a bump to it now that the lights are

sunked in lower into the bumper

Oct 25 0.5hr

Sanded down some of the fenders filler to see how much more work it

needs

Oct 27 5hr

Bit longer day then normal but lots of different things got

accomplished. To start with all the molds where trimmed

drilled. Any parting on back firewall was ripped and relocated to

other areas to extend part lay up. Got it waxed but did not PVA so

will see how that will work with separation of mold panels.

All the mold's will need to have second look as normal before making

parts and should do that ASAP to the parts can be laid up though it

might be good idea to have them cure and settle for couple of days.

Got the speaker boxes trimmed and filled in some chips and back side

so that the extra mount pieces molds can be made in the next couple

of days

Oct 28 1hr

Laid up window surround return however used brush technique to

apply resin into the mat.

Couple observations from the process. Its a lot slower then doing it

by hand, possibly uses more resin during the process. .... Oh did I

say its a lot slower. On positive side. its possible to brush fibers

smoother

Oct 31 4.5hr

Laid up bottom return on rear firewall panel, will let it sit for

couple of days before trimming and getting the molds ready for

making part. Sanded down speaker boxes plugs and primed , however

will have to skim it again to fill in couple small indentations not

that it would show bit I would know that they are not done properly.

Thou thinking about it they can be sanded down on the molds to have

it corrected. Cleaned up all molds for HVAC and speaker boxes,

unfortunetaly will have to fill in couple spots as the it looks like

the mat pulled off around corners. Also it ssems there was bubbles

in some spots of the mat was not saturated enough. SO.... I think

its best if those spots get corrected before making parts, extra

couple hours but it will be worth while.

To mix things up worked more on fenders surrounding headlight

openings and trying to get them raised and into shape and also

around hinge indents getting them smoothed out.

Should get the sill returns part of fenders extended, not sure if it

was miscalculation in having them trimmed or bolt holes in fenders

or door hinges or just combination of all above. Never the less need

to get them extended and box made around the hinge it self. So will

try to do that in the next couple of days.

Nov 2 2hr

now that couple days had passed and the firewall panel had time to

setup went out trimmed all the loose left overs drilled and pulled

molds from the plug. Not sure what had happened but there was couple

dry spots on the main and around window return that will have to be

filled up and sanded down before making part. While at it, touched

up HVAC and speaker boxes molds. However with fall coming faster

then expected temperatures are cooler so the curing starting to

extend so will have to wait till next day. Last thing for the day

decided to fill in some of the spots in speaker boxes as it will be

easier and faster to have it corrected this way then doing after the

fact. Not sure if it will be best to make just the parts or molds

and pull parts out. Either way its getting late in year and like to

have the parts made so will be able to have mounts made over the

winter time and any other mounts that are still missing.

Nov 6 4.5 hr

Been busy last couple of days, however got out today and made some

progress on the molds and got them ready for part making. Got all of

the goop and filler sanded down from pulling them from the plug. All

of the fillings got sanded including speaker boxes plugs to pull mol

for reinforcing ribs. All of them are waxed and PVA. Providing will

have enough resin then all of the HVAC, speaker boxes and rear

firewall upper panel will be make next day. Will have to do the

speaker and storage cover most likely next year.

Sanded down left fender and hinge packets. Will have to dust it off

and prime it to see if there are any spots that will need to be

fixed. Lastly ground down inner sill returns so will have to make up

recesses and extensions and have them glassed in before bonding to

the fenders.

Nov 7 4.5hr

seasonal wormer day so got out to garage for few hours. Assembled

all molds together and laid up speaker boxes and firewall cover

panel. Running low on resin but should had laid up last mold from

speaker box. May be will do that next day and assemble the speaker

boxes

Nov 10 .5hr

Split up the parts from the molds and though did not used any gel o

those they actually came out not too bad. Couple spots will need to

be fixed and sanded down but over all they are good and after they

are covered the gel coat will not make any difference. They are only

3 layers of 15oz with extra layer o2 around mounting holes, seem to

be strong opposed to thicker ones and are light especially

unexpectingly rear cover panel

Nov 13 2hr

Had been cooling down over last week but decided to grin and bear it

and get last parts done. Did not bothered to pick up extra resin so

was bit hesitant on making any as it would not had enough.

Surprisingly laid up the 2 HVAC boxes and supports for speaker

boxes. not sure if should just use the parts or pull parts for the

supports. Would have to get more resin as it was just used last

ounce on them

Pail of resin might be bit much if only used few onces and not sure

how it would hold over winder. Might be able to six fenders or

possibly pull molds but would require a lot of work on them still

and that might be pushing into december. So may just concentrate on

what is made have it trimmed and fitted and maybe do some work on

the doors like window regulators and latches

Jan 3 2022

No excuses as could have put more time into the project and only

moderate 236 hours where spent on the project

2020 may have looked unproductive as a lot could had been completed,

though it was a very good year overall with only 216 hours applied to

the project which gave a very good start to other things that can be

worked on and hopefully completed this year. A lot of the time was

applied to the interior plugs from which parts where pulled. Some

work still is pending to have them finished but they are nearly

ready with few more to go next year.

..... so on to the next year and hopefully closer to have it

finished

Total

1498.

hr