|

|

|

|

|

|

Interior fuse box

Work had started on the part, it is progressing and will be updating content

on this page often, please come back soon and often for updates.

We like to use as many OE parts as possible and not re-inventing new wheel if

it is not necessary. However at some time there will be need to at least

modify it to either fit the need or because you like to have it make it your own

version of it.

We wanted to use a readily available fuse box that is modular with lots of fuse

buses and relays that we could use for security and as Body Control Module, a

BCM for short. Which would allow it to be used as security device and have

flexible connections.

Had looked at various setups in different makes and models of vehicles and can

be categorized in couple groups.

- simple fuse block, small and compact with no relays

- combination units in configurations with relays but odd shaped as per

manufacturers needs

- small (ish) more complex units with replays, lots of fuses with modular cable

connectors but no electronics

compartment

- modular units with relays, fuses and compartment for electronics (BCM), but

extremely large and odd shaped

One setup from 3rd generation Acura TL or 7th generation Accords that stood out

as it is fairly compact, has lots of fuses and relays controlled by built in BCM

module in the back of the box. Cable harnesses with connectors going to various

corners of the car making it very modular. including a harness that goes to the

steering wheel switch stalk that is wired through CAN bus. One problem with the

BCM is that the electronics is controlled by security function between ignition

key and linked to ECM module. So unless the entire electrical system is

installed / transplanted the fuse box is useless unless the BCM electronic

module is reprogrammed which would be very hard with out any of Hondas

documentation manuals or replaced by custom made module

|

|

Fisrt impression of the BCM is that its fairly complex and has number of

functions

- internal interface to relays, fuses and sensors

- external 2 connectors for various sensors and interface to stalk

switches

- relay control in the fuse box

- key identification (security)

- door locks

- turn signal controls

- light controls

- interior light control

- CAN (single wire CAN 33Kb) low speed interface to alarm and other

modules with in the car

- acts as bridge interface to instrument cluster by sending CAN

messages reducing connections to the cluster.

To replicate the module will require knowledge of all connections and

understanding of specific CAN messages which are readily available through

number of publications. |

BCM printed circuit board

|

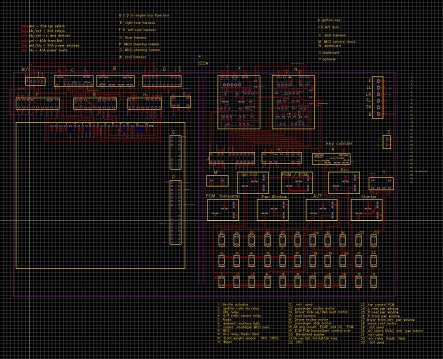

First step is to revere engineer interconnections between all of the connectors,

fuses and replays.

by opening the case the case, back side reveals BCM PCB plugged into 25

pin internal connector on top of a sand witched 7 layer heavy trace layered

assembly that routs various wiring pathways between all the connectors relays

and fuses. With the assistance of CAD program, all connection points where drawn

up and using a multi meter each connection point was carefully traced and marked

with appropriate signal name. By putting a mouse pointer on particular pin it is

very easy identifiable of where that particular interconnection is split and

goes to.

Further to assist labels where added on each connector pin of where it is going

to and being used for. Respectfully each wire on harness was also labeled for

easy identification later on when modifying each harness will be required.

|

Fuse block connection map |

With all of the interconnections decoded, its time to make the new BCM

control board. Connectors on the board can not move as they are need to follow

internal pins and same will apply to the external connectors P & Q will

change some locations for some of the pins as that the harnesses will be more be

more direct connection between the fuse box and rest of the sensors with in the

car.

Will also keep window regulator control relays along with all the other

functions of the BCM. Howerver will use a newer processor in place of the

original Motorola one.

With that in mind a new PCB was created in same size with internal connector

pins and mounting holes as the OE. CAD connectors profiles for P & Q where

created and placed in original locations.

|

|

|

Firmware ?? |

|

|

|

All content is copyrighted 2014

|