With body being made out of multiple panels, we needed them to be easy removable

for maintenance of replacement n case of accident. Therefore the mounting needed

to be done with bolts rather then bonding method or welded onto the frame with

embedded metal pieces into the panels.

With the exception of the windshield frame/surround / and A pillar which is

bonded onto the windshield frame A pillar sub frame with poly urethane. All

remaining panels are bolted directly to the chassis. In order to do

that the chassis was made in a way that strategically located mounting tabs and

weld in nuts into the chassis tubes are virtually leaning against the panels.

There small gaps left to either fill in with fiberglass filler to compensate for

variations in panel thicknesses or just to have a smooth surface to mate against

a tube when then was cushioned with rubber as anti-vibration or make it water

tight.

With the panels being bolted directly onto the chassis, the added benefit was

that all of the chassis tubes where able to be pushed as far out as possible

thus providing biggest possible

space for creature comfort plus making as much space as possible to the systems.

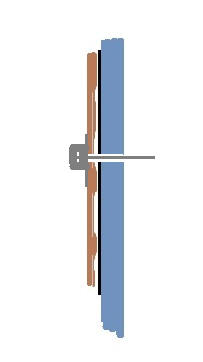

Panel to chassis mounting

Picture to the left shows off typical panel to tube mounting with welded in rod

that is drilled through and tapped to receive a mounting bolt illustrated by the

thick blue line.

The brown line is a body panel, flat on outside and surface variation towards

the tube.

white void is area filled in with filler making part of the body panel

The black line is the rubber or foam membrane that prevents squeaking and makes

water tight

Gray is a bolt with oversized washer against the fiberglass preventing

possible cracks in the panel.

Similar process is applied to panels that are bolted to a tab rather then a tube

but over a smaller area of the body panel

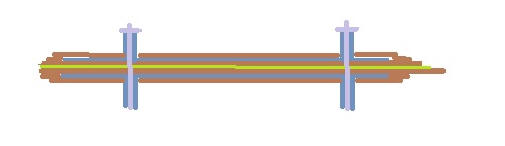

Panel to Panel mounting

Panel to panel mounting are bit different of how they are mounted or

bolted together.

Main reason for doing so is that there is no chassis that the panels or

joints between the panels that could be bolted to.

The panels have fiber glassed in metal standoffs on each panel directly facing

each other. Those stand offs are also welded into a sheet metal which painted to

prevent rusting. One side is over drilled so that bolt would thigtly fit into

the hole and other stand off is threaded. So by having 2 or more of this type of

stand offs that are bolted together provides ridgity to the mounting from

vibrating or moving around. From picture above the yellow line is the gel coat

or paint that's on the panel. In blue is the sheet metal and stand offs

that are fiber glassed in and represented by the brown area.

One of the mounts is between rocker and quarter panels. The panel joints are of

triangular shape and having 3 bolts. This way the panels can not bowl or twist

and thus not making the contour of the body to change.

Second place where this type of joint is used is with lower diffuser. However in

this case the diffuser is bolted to the chassis. Then lower part of quarter

panels are then bolted with 2 bolts on each side to the diffuser. In this

situation, with diffuser being mounted to the chassis prevents moving sideways

and having 2 bolts on the sides prevents the diffuser and in a way quarter

panels from sagin beging the rear wheel

... More Content Coming Soon

Panel bonding (windshield frame)

There is only one body part that is bonded to a frame and that's the windshield

frame it self. As the windshield frame and A pillars are one unit and made

to me removable by removing few bolts that are used to fasten it to the main

chassis. It is possible to have the windshield frame and body panel bonded to

each other.

... more content coming soon

Panel frame reinforcement

With some larger panels like engine lid, front trunk, doors and roof there is a

metal frame that is bonded into the body component doors specifically or

sandwiched between 2 fiberglass panels. The metal frame adds mounting points

for bolts and also provides re-inforcment to the large fiberglass panel.

... more content

coming soon |